Introduction:

Toyoda designed and developed various material-centered weaving gadgets, acquainting imaginative energizing frameworks used with power by his Toyoda-marked machines. His most renowned development was the programmed power loom in which he executed the standard of Jidoka (self-ruling mechanization). The rule of Jidoka, which implies that the machine stops itself when an issue happens, turned out to be later an aspect of the Toyota Production System [1]. Some many inventors and Scientists invented Benz Company by Karl Benz, Yamaha Company by Torakusu Yamaha, Kawasaki Bikes by Kawasaki Shōzō, Ferrari by Enzo Ferrari, and many others who worked for the nation and country. They became famous all over the world. Here, we will Sakichi Toyoda | discuss founder of Toyota Industries.

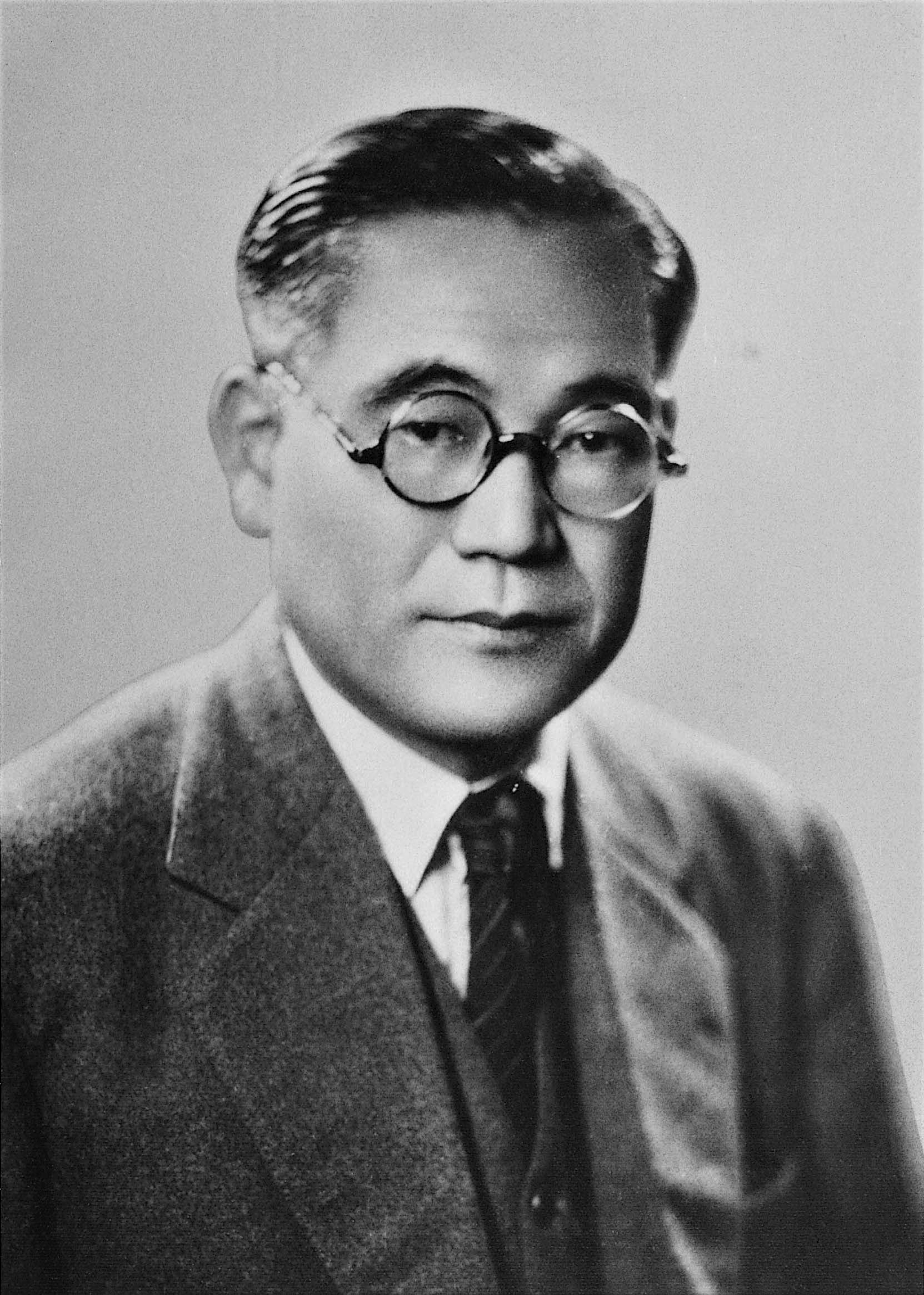

| Basic Information | Sakichi Toyoda |

| Date of Birth | 14th February 1867 |

| Place of Birth | Kosal, Shizuoka, Japan |

| Age | 63 years old |

| Date of Death | 1930 |

| Place of Death | Nagoya, Aichi, Japan |

| Founder / Owner | Sakichi Toyoda founded the Toyota company in 1926 |

| Business | Founder, Toyota Boshoku Corporation, Toyota Industries, currently became the Toyota Group |

| School | Elementary school |

| Investment | To invent for making cars |

| Famous | Famous for the Owner of the company |

| Other Activities | Making the wooden looms. |

Early Life and Automaker of Toyota Company:

Sakichi Toyoda was born on 14th February 1867 in Kosal, Shizuoka, Japan. He was a Japanese industrialist and inventor. He was the son of a farmer who worked as a carpenter. His son Toyoda made the family of Toyoda companies. After some years, his son Kiichiro Toyoda became the largest automaker of the automobile [1].

Toyoda Automatic Loom Works:

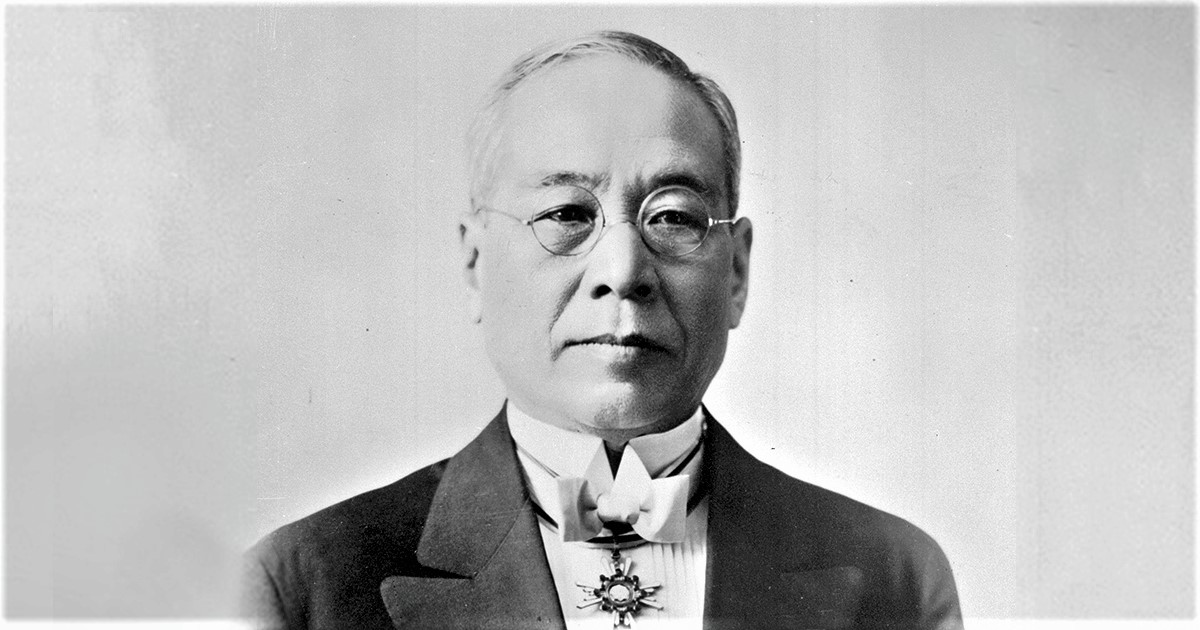

Toyoda Automatic Loom Works was the designing assembling organization set up by Sakichi Toyoda in 1926. It gained him the moniker of the father of the Japanese modern upheaval. He is likewise the author of Toyota Industries Co., Ltd [1].

Toyoda built up the idea of 5 Why’s: When an issue happens, ask “why” multiple times to discover the wellspring of the issue, at that point set up something to keep the issue from repeating. He used this idea today as a feature of applying lean procedures to take care of issues, improve quality, and lessen costs [1].

The Family Tree of Toyoda Company:

Sakichi’s introduction to the world and early childhood agreed with that period in Japanese history when the shogunate had been supplanted by another administration under the Meiji Emperor. This period was mostly viewed as the start of present-day Japan. In social changes, they tormented the entire town where Sakichi lived with neediness. From the age of 14 or 15, Sakichi considered manners by which he could both be valuable to the individuals around him and serve his nation. On days when there was no carpentry, Sakichi would steadily understand papers and magazines. He united the nearby youth in a night study bunch that advanced self-learning. He couldn’t think of approaches to add to society [1].

Learning of Sakichi for Making Monopoly Act:

Sakichi turned 18 every 1885. He learned of the recently ordered Patent Monopoly Act. This he concentrated cautiously and immediately became persuaded that he had discovered his way forward. Without even a moment’s pause, he took advantage of his shrewdness and dedicate his most extreme actions toward development as a method for making something new. “Western human advancement depends on the apparatus. Steam drives machines. Steam-controlled apparatus requires costly coal. Some strategy must supplant steam as the rational power.” So, thought Sakichi. Using experimentation techniques, Sakichi tried different things with different perpetual and boundless fuel sources. He was not effective [1].

Inspiration From the Handloom Wooden Machine:

In this design, Sakichi kept on contemplating. Eventually, he got inspired by the handloom used by neighborhood ranch families. Sakichi believed that on the off chance that he could figure out how to improve the proficiency of the handloom, it would profit many individuals. Sakichi set to work. Working in an outbuilding, he assembled and pulverized various weavers. A few people considered him being peculiar. Inundated in his activities, this didn’t trouble him by any means [1].

Move to Tokyo for Third National Machinery Exposition:

In 1890, Sakichi went to Ueno in Tokyo to visit the Third National Machinery Exposition. Many new machines of both Japanese and abroad assembling were in plain view. Sakichi had profoundly intrigued. So much that he went through consistently for the following month visiting the piece, resolved to see how every the machine functioned. In the harvest time of the very year, Sakichi’s first fruitful innovation had refined. He had known as the Toyoda wooden handloom. Sakichi got his first patent for that loom in 1891. He was 24 years of age [1].

Quality of the Wooden Hand Loom:

In contrast to past weaving machines, Toyoda wooden handloom required just one hand to work rather than two. It eliminated the lopsidedness of the woven texture, hence improving quality. It expanded proficiency by 40 to 50 percent. The loom had still physically fueled. This restricted further upgrades in speed and productivity. So, Sakichi directed his concentration toward the innovation of a force loom [1].

Made a Small Business in Tokyo City:

In 1892, Sakichi began a little production line in Tokyo’s Taito Ward that used a few of the Toyoda wooden handlooms designed by Sakichi. He did this for a few reasons. He needed budgetary autonomy to more readily seek after his designing profession. Toyoda required assets to help his happenings. He additionally imagined that he would be ready to certainly prescribed his innovation to clients by utilizing it himself to affirm its boss presentation [1].

Fabrics Selling to the Wholesale Dealers:

Textures fabricated by Sakichi’s plant had dispersed to wholesalers and appreciated decent notoriety. Sakichi dealt with the activity while proceeding with his creating goings-on. Sadly, the production line didn’t progress admirably and must be closed down following a time of activity. Sakichi got back to his old neighborhood. Before long thereafter, he went to visit an uncle living in the city of Toyohashi in Aichi Prefecture. He lived in his uncle’s home and proceed with his activities toward building up a force loom [1].

Toyoda Winding Machine:

For making more income he did hard work and invent the highly efficient Toyoda Winding Machine in the year 1894. This was an epoch-making development. For promoting the manufacturing and the selling of his new machine, he built a new company, of which name was Ito Shoten Co., a negotiator for the Toyoda, in Nagoya. After some years this became the Toyoda Shoten CO. and after that Toyoda Shokai Co [1].

The invention of Power Loom:

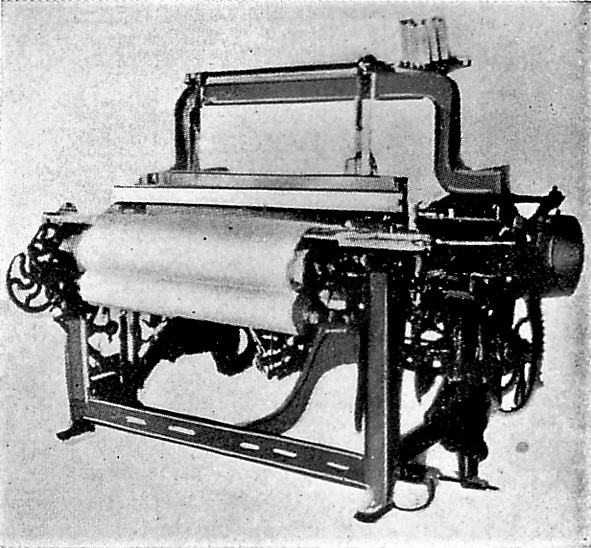

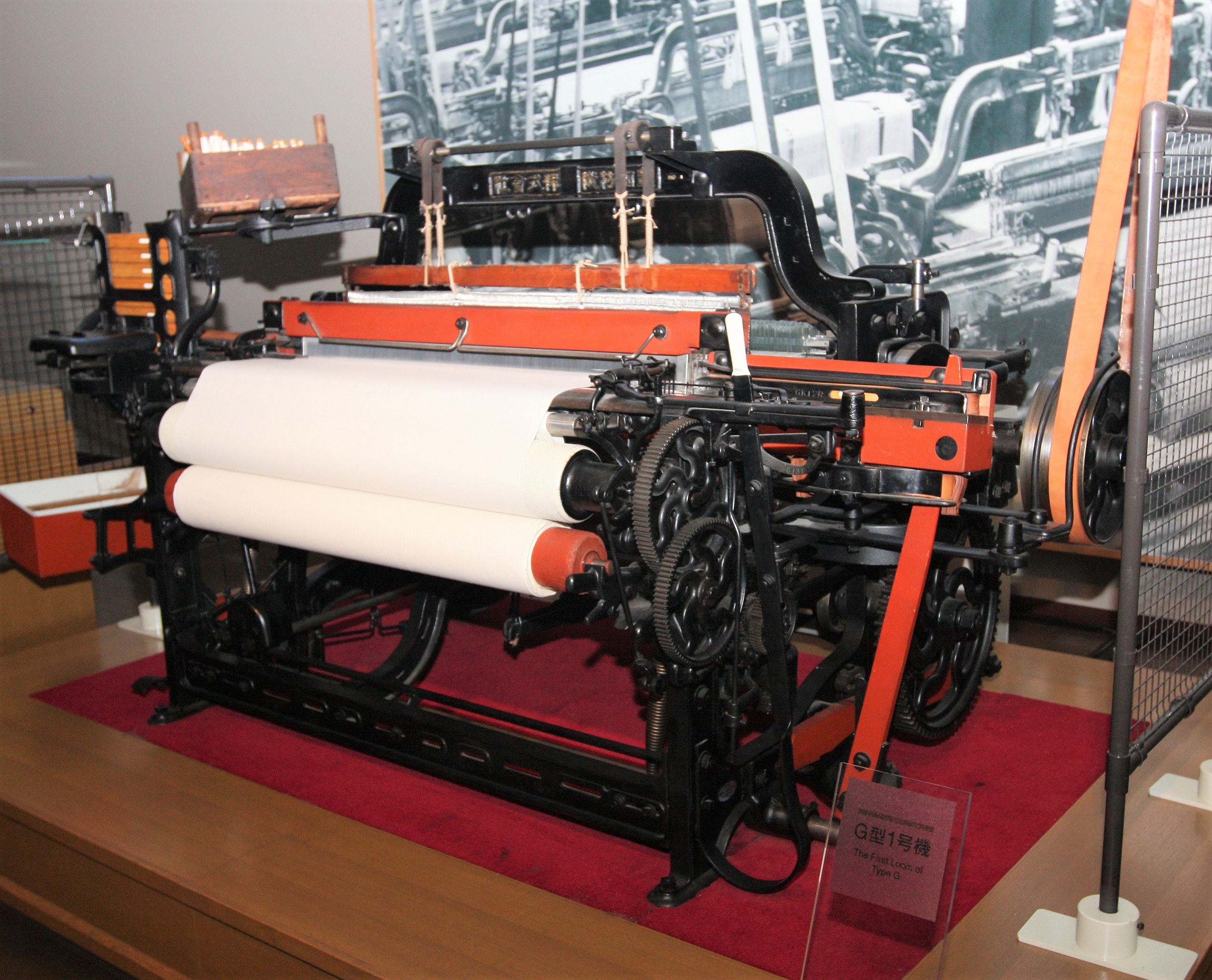

When deals of the winding machine were on target, Sakichi directed his unified concentration toward imagining a force loom. It didn’t take him long. In 1896, the Toyoda power loom, Japan’s first force loom worked of steel and he culminated wood. The shedding, picking, and beat-up movements were all steam-controlled. He likewise furnished it with the weft auto stop instrument. The machine was reasonably and enormously expanded, profitability and quality [1].

The New Customer for Toyoda:

One of the first to perceive the remarkable execution of the new loom was a client of Toyoda Shoten Co. named Tohachi Ishikawa. He proposed opening a weaving business. He and Sakichi were before long accomplices. They established Okkawa Mempu Co. in Aichi Prefecture’s city of Handa. The top-notch cotton material woven by the new loom gained notoriety for greatness [1].

Using Steam Engine and Motor Oil:

Sakichi used not only the steam engine but also used the motor oil as a power source for his looms making. The loom before long went to the consideration of Mitsui Bussan (right now Mitsui and Co., Ltd.). In 1899, they proposed setting up a loom-producing organization. I get a Shokai Co. had set up with Sakichi managing the creation of intensity looms as a boss architect and completely committing his actions to additional development. Monetary conditions were terrible, and the organization ran into some bad luck, making further advancement increasingly troublesome. Sakichi, at last, left the organization and opened the autonomous oversaw Toyoda Shokai Co., where he committed himself to development and examination.

Sakichi proceeded with his happenings to improve his machines. Weaving machines, a bobbin to hold the weft. At the point when the weft ran out, he must halt the force loom to renew it. This vacation incredibly diminished operational effectiveness. Sakichi got zeroed in on the assignment of developing a gadget that could consequently supplant the bus when the weft ran out [1].

An Unwavering Conviction of the Commercial Trials:

In 1903, Sakichi designed the primary programmed transport changing instrument that naturally renewed the weft yarn ceaselessly machine activity, creating the world’s first transport change programmed loom, Type T, furnished with this system. Kanegafuchi Boseki Co. joined this bus changing system to its wide weavers attempted execution testing. The test outcomes, notwithstanding, were not all that positive because Sakichi had depended on the structure and pre-testing to other people. Considering this experience, he built up a steady conviction that I should never sell an item except if it has been painstakingly made and completely tried in the business preliminary, with totally palatable outcomes [1].

As it will be reference thereafter, Sakichi later headed out to the United States and Europe on a perception trip. He visited Dr. Jokichi Takamine at his home in New York. He widely acclaimed or Takamine for having been the principal individual to effectively separate Taka-Diastase and adrenaline. Dr. Takamine clarified a designer should never place their innovation in the possession of others until it had been created as a functional item with helpful social outcomes and that this was the obligation of a creator. Sakichi had roused and accepted this counsel to heart [1].

Toyota Power Looms in 1905:

In 1905, Sakichi concocted the Toyota power loom, 1905 sort, furnished with the improved twist let-off system. The loom likewise had a sound structure, worked of wood and steel. An improved variant called the Toyota power loom, 1906 sort continued this in 1906. The 1906 sort significantly improved proficiency and texture quality [1].

Other Extreme Aim:

In 1906, Sakichi likewise acknowledged what he viewed as the other extreme aim other than the innovation of the programmed loom developing an energy-productive roundabout loom that wove fabric through an ideal round movement. Until this time, looms used an even complementary movement to move the bus conveying weft and weave. Paradoxically, the round loom used a roundabout movement to move the van and the weft addition and beating had done unobtrusively and uninterruptedly. This had never been finished [1].

Overcoming Setbacks:

In the year 1907, by the recommendation of Mitsui Bussan, Toyoda’s Loom Works, Ltd. (presently Howa Machinery, Ltd.) had established with funds provided by the investors in Tokyo, Osaka, and Nagoya. So, the new company took control over the plant, and Employees of Toyoda Shokai Co. Sakichi assumed that the duties of managing the director, chief engineer, and sustained to dedicate his labors to plan and investigate [1].

Regardless, because the new organization didn’t permit business preliminaries for which Sakichi held such a solid conviction, he set up his own only worked business preliminary plant (later Toyoda Shokufu Kikui Kojo) in 1909. Toyoda’s Loom Works, Ltd. was in the long run assailed by helpless business results, causing Sakichi grave worry as he was the central architect taking care of development and research and a chief who couldn’t disregard the executives of the organization. In 1910, Sakichi left Toyoda’s Loom Works, Ltd. also, set out on a perception outing to the United States and Europe to make a new beginning [1].

The Production of Weaving Plants:

Sakichi went toward the West Coast of the United States from where he navigated the nation. He visited many weaving production lines in the Upper East Coast district. While stunned at the size of these activities and their test offices, he saw many faults in the weavers there and had not intrigued. Sakichi at that point ventured out to England where he visited loom producers and weaving plants in the Manchester zone. This perception trip imparted to him with trust in the prevalence of his unique loom. He advanced back to Japan revived [1].

The Strong Commitment of Invention:

After he came back to his country from the trip to the United States and Europe, Sakichi increased the labor in 1911 and established the independently operated Toyoda Jido Shokufu Kojo (Toyoda Automatic Weaving Mill) which provide the ground for the inventors in the Noritake-Shinmachi area of Nishi-Ward, Nagoya. The invention and perfection of his automatic loom, however, did not Diminish Sakichi for the creation as the conclusion of the round loom which is continued to be his enduring detection [1].

Toyoda Automatic Loom Works, Ltd. Sets Sail:

Following the successful development of the automatic loom, so that on 17th November 1926 which is the incorporation meeting of the Toyoda Automatic Loom Works, Ltd. Which is currently called the Toyota Industries corporation, this had held in the head office of Toyoda Boshoku in Nagoya City. The worldwide recognition of a Japanese invention and the request from the foreign company for a patent rights transfer were a truly striking events in the technical history of Japan and the imparted sureness in many Japanese [1].

Death of Toyoda Sakichi:

The owner of the Company Toyoda Company passed away in October 1930, who spent the life of 63 years there for the inventions. After his death, there were about 13,000 workers in the company which was gradually increasing [1].

References:

- mathshistory.st-andrews. 19th October 2020; Available from: https://mathshistory.st-andrews.ac.uk/Biographies/Suzuki_Michio/

5 Replies to “Sakichi Toyoda | founder of Toyota Industries”